Solutions

At Manufacturing Technology Project (MTP), we develop next-generation computational technologies that elevate digital manufacturing across metal, energy, bio, and semiconductor applications. Our solutions combine high-fidelity physics, advanced AI, and scalable digital twins to empower engineers, researchers, and manufacturers:

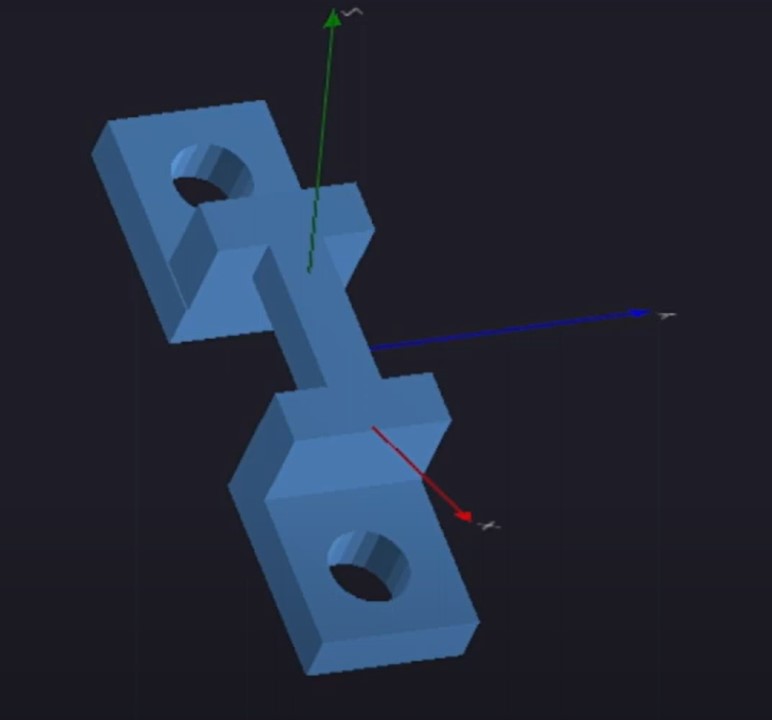

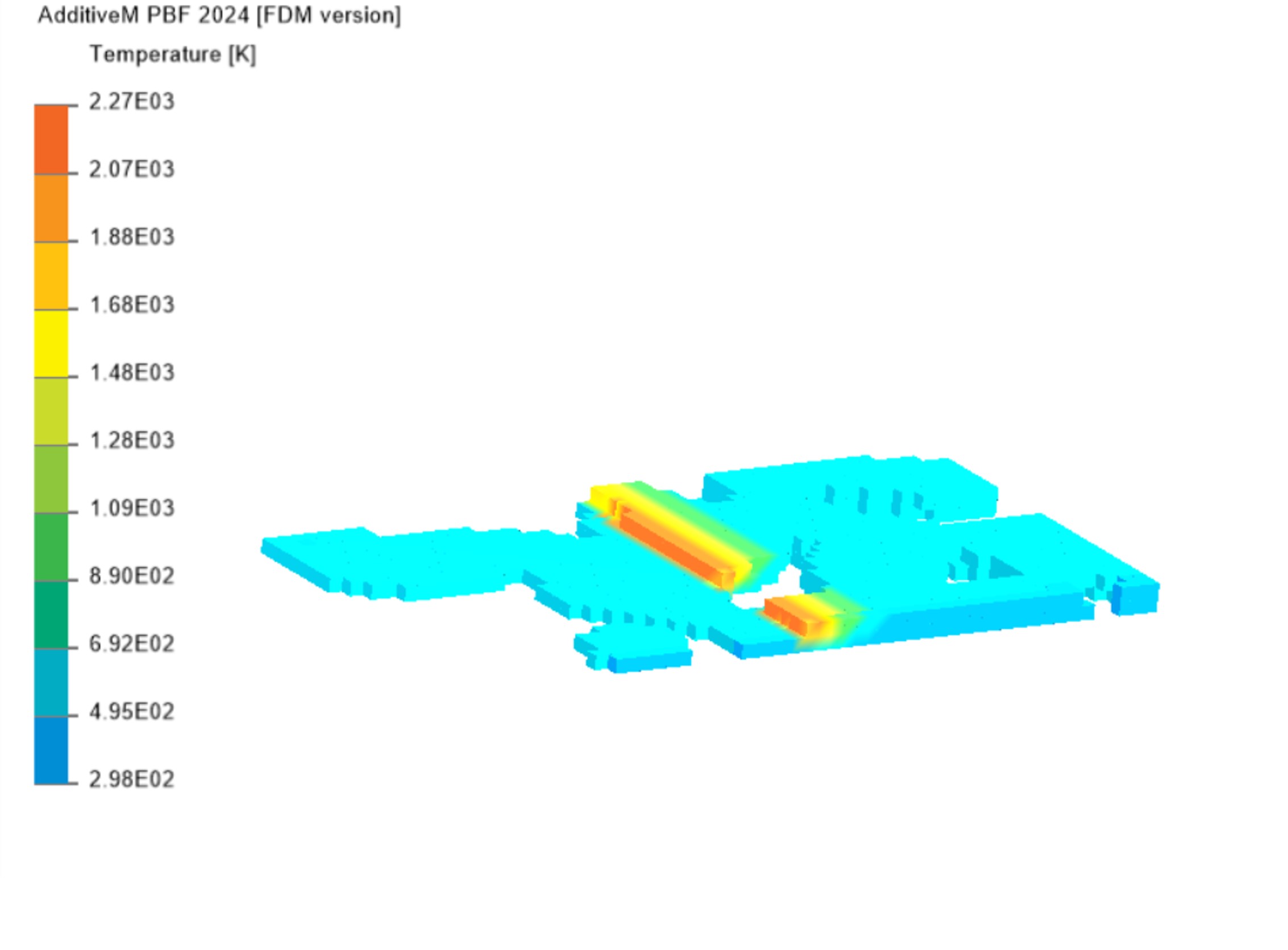

- High-Fidelity Thermomechanical Simulation: Our flagship platform, AdditiveM, delivers advanced thermomechanical simulations for metal additive manufacturing. From powder-bed fusion to directed-energy deposition, AdditiveM enables precise temperature, stress, distortion, and microstructure prediction with engineering-grade accuracy.

- Real-Time Data & Digital Twins: Integrate real-time data into your simulation and digital twin workflows. MTP tools process and analyze data instantly, allowing manufacturers to make fast, informed decisions that optimize print quality, reduce defects, and accelerate development cycles.

- Customizable & Modular Modeling Frameworks: We understand every project is unique. MTP software allows users to tailor all modeling parameters—geometry, mesh resolution, material models, heat sources, boundary conditions, and control algorithms—to reflect the exact needs of their process or research environment.

-

Comprehensive Manufacturing Process Modeling

Our solutions span a broad range of additive and advanced manufacturing processes, including:- Powder Bed Fusion (PBF) with AdditiveM Software

- Directed Energy Deposition (DED) with AdditiveM Software

- Molten Metal Deposition (MMD) with AdditiveM Software

- Energy Systems Simulation with LithiumX Software

- Bioprinting with AdditiveBIO Software

- Silicon Fabrication Modeling with SiliconX Software

Our Commitment

At MTP, we are redefining digital manufacturing through computational precision, AI-enhanced modeling, and intelligent design. Whether you are developing next-generation metal components, optimizing energy materials, or exploring biomedical or semiconductor fabrication, MTP provides the computational backbone needed for accuracy, efficiency, and innovation.

Explore our rapidly expanding ecosystem of digital manufacturing technologies and see how MTP helps engineers, companies, and research teams stay ahead in the evolving world of advanced manufacturing.

Our Mission

To redefine digital manufacturing by developing high-fidelity, AI-enhanced computational tools and digital twins that empower engineers, researchers, and companies to design, simulate, and optimize metal, energy, bio, and semiconductor systems with unprecedented accuracy and efficiency.

Our Plan

- Expand Software Offerings: Continuously develop and release new computational packages tailored to various additive manufacturing techniques, ensuring comprehensive coverage of industry needs.

- Enhance User Experience: Invest in user-friendly interfaces and support services to make our tools accessible and efficient for all users, from students to industry professionals.

- Foster Innovation: Collaborate with leading research institutions and industry partners to stay at the forefront of technological advancements and incorporate the latest innovations into our solutions.

- Global Outreach: Expand our market presence globally, making MTP's advanced computational tools available to manufacturers worldwide, fostering a new era of digital manufacturing excellence.

- Expand Integrated Platforms: Advance and integrate our core products AdditiveM, LithiumX, SiliconX, and AdditiveBIO into a unified digital-twin ecosystem for advanced manufacturing.

- Enhance User Experience: Build intuitive interfaces, rich learning resources, and responsive support to make sophisticated simulation accessible to students, engineers, and industry experts.

- Foster Research & Partnerships: Collaborate with universities, research centers, and industrial partners to co-develop validated models, novel methods, and real-world case studies.

- Global Impact & Education: Grow MTP’s global presence while providing educational tools and training that help the next generation of engineers master computational thinking and digital manufacturing.

Our Vision

To be the computational backbone of advanced manufacturing worldwide—linking physics-based simulation, AI, and digital-twin technologies to enable smarter metal AM, cleaner energy systems, pioneering biomedical solutions, and next-generation semiconductor and space applications.

High-Fidelity Metal AM Simulation with AdditiveM

Build trusted digital twins for metal additive manufacturing using AdditiveM. Our multiphysics solvers capture temperature, stress, distortion, and defect-sensitive behavior across powder bed and directed energy processes.

- Multi-Process Coverage: Simulate Powder Bed Fusion (PBF), Directed Energy Deposition (DED), and Molten Metal Deposition (MMD) within a unified framework.

- Thermomechanical Accuracy: Resolve thermal histories, residual stresses, and distortion for critical parts, enabling better support design and process windows.

- Custom Material Models: Implement user-defined alloys, microstructure-aware behavior, and calibration workflows tailored to your printers and materials.

Process Optimization for Metal, Energy, and Beyond

Use simulation-driven workflows in AdditiveM and LithiumX to explore process windows, reduce trial-and-error, and design more robust manufacturing strategies.

- Simulation-Driven Design: Link CAD and simulation to optimize scan paths, layer strategies, currents, and thermal management before committing to hardware.

- Design Space Exploration: Run automated studies and parametric sweeps to quantify sensitivity to process parameters and identify safe, high-performance regimes.

- Predictive Process Control: Combine models with real or synthetic data to support predictive adjustments, minimizing scrap and improving consistency.

End-to-End Digital Twin Workflows

MTP tools are designed to fit directly into your engineering workflow—from geometry, meshing, and process definition to data analytics and reporting—so digital twins become a practical everyday tool, not a research experiment.

- Seamless Integration: Connect our solvers with your existing CAD, meshing, and data infrastructure to create continuous model-to-manufacturing pipelines.

- Automated Workflows: Script common tasks, batch-run scenarios, and standardize post-processing to save engineering time and reduce human error.

- Scalable Architectures: Deploy from a single workstation to cloud or cluster environments as your project size and team grow.

Innovation Across Energy, Bio, and Silicon

Partner with MTP to prototype the future of manufacturing—whether it is advanced batteries, patient-specific implants, or semiconductor processes—using LithiumX, AdditiveBIO, and SiliconX.

- Energy Systems & Batteries: Model thermal behavior, state-of-charge effects, and fast-charge strategies with LithiumX.

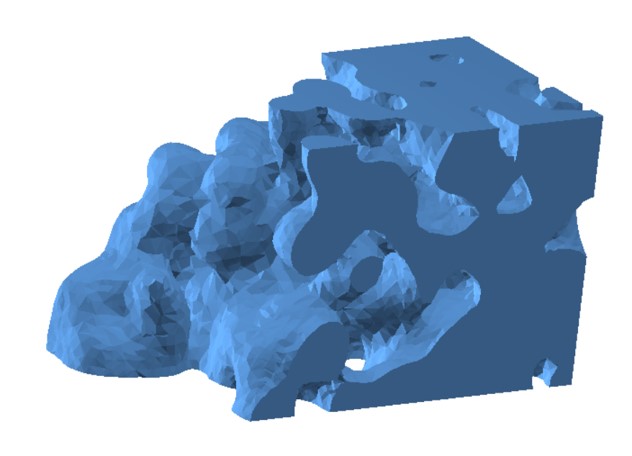

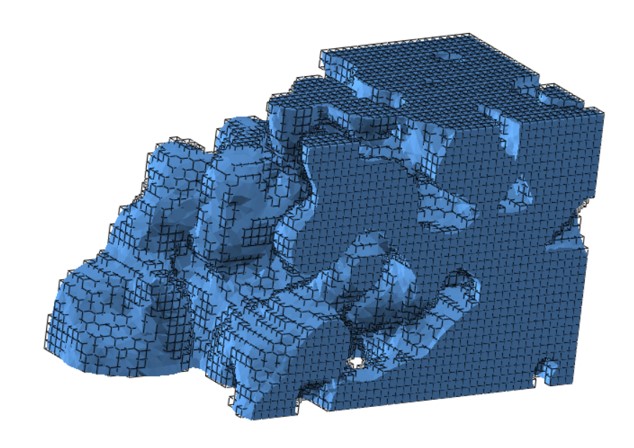

- Bioprinting & Implants: Explore bioprinting workflows and digital twins for orthopedic and soft-tissue applications with AdditiveBIO.

- Silicon & Advanced Fabrication: Use SiliconX to investigate process conditions and device-scale behavior in silicon fabrication and related applications.

Innovation

MTP develops next-generation computational technologies that integrate physics-based modeling, AI-driven intelligence, and scalable digital twins. These innovations empower engineers, companies, and researchers across metal AM, energy systems, silicon fabrication, and biomedical manufacturing.

Advanced Metal AM Simulation

High-fidelity thermomechanical simulation through AdditiveM, enabling accurate prediction of temperature, stress, distortion, and defect-sensitive behavior for PBF, DED, and MMD processes.

Cross-Domain Digital Twin Platforms

Unified computational platforms—including AdditiveM, LithiumX, SiliconX, and AdditiveBIO—that streamline design-to-manufacturing workflows across metal, energy, silicon, and biomedical systems.

AI-Driven Process Optimization

Machine learning and physics-informed neural networks (PINNs) accelerate design exploration, optimize process parameters, and enable smart manufacturing through predictive and adaptive control.

Multi-Scale & Multi-Physics Modeling

Linked micro-to-macro simulations for metal AM, electrochemical systems, bioprinting, and silicon fabrication—delivering deep insights into material behavior, process evolution, and performance outcomes.

High-Fidelity Thermal & Stress Analysis

Advanced modeling of heat flow, solidification, residual stress, and deformation ensures accurate reliability predictions and supports defect reduction for critical manufacturing applications.

Integrated Simulation & Workflow Frameworks

End-to-end frameworks coupling FEA, CFD, DEM, thermal-electrochemical models, and AI—providing comprehensive digital insights and seamless integration into engineering and manufacturing pipelines.

Downloads

Computational Techs

- All Technologies

- Metal Additive Manufacturing

- Energy & Battery Manufacturing

- Semiconductor Manufacturing

- Biofabrication & Bioprinting

Starting from $59.99, tax excluded

Starting from $59.99, tax excluded

Starting from $1499.99, tax excluded

Starting from $1499.99, tax excluded

Starting from $1499.99, tax excluded

Starting from $1499.99, tax excluded

Starting from $1999.99, tax excluded

Starting from $1999.99, tax excluded

President's Note

Welcome to the Manufacturing Technology Project (MTP)

Hamed Hosseinzadeh, Ph.D.

President & Chief TechnologistA Message from the President

As President of MTP, it is my privilege to welcome you to a company built around one core idea: advanced computation can transform manufacturing. At MTP, we are redefining digital manufacturing through high-fidelity physics, AI-enhanced modeling, and intelligent digital twins.

Our journey began with AdditiveM, a metal additive manufacturing simulation platform for PBF, DED, and molten-metal processes. Today, that vision has expanded into a broader ecosystem that includes LithiumX for energy systems, SiliconX for silicon fabrication, and AdditiveBIO for bioprinting and medical applications. Together, these tools provide a computational backbone for advanced manufacturing.

Innovation is at the heart of everything we do. We integrate multiphysics simulation, AI, and digital-twin technology to help our partners reduce risk, accelerate development, and explore designs that would be impossible with trial-and-error alone. Our collaborations with universities, research institutions, and industry partners keep MTP at the forefront of emerging technologies.

We recognize that every organization faces unique challenges. That is why we focus on configurable, project-driven solutions and long-term partnerships rather than one-size-fits-all software. I invite you to explore MTP’s platforms and to contact us to discuss how we can support your work in metal AM, energy, bio, or silicon manufacturing.

Contact

Contact Us

Our Post Box

100 Springdale Rd, Ste A3, PMB 403, Cherry Hill, New Jersey, USA, 08003

Email Us

info@manufacture.technology

Support@manufacture.technology